Drug Delivery Device Inspection

Checking drug delivery devices for product integrity, including pumps and injectable pens.

Over 20 years ago, we developed highly sensitive inspection systems that could measure the dose level of powdered drugs, since then we have worked with R&D teams worldwide on a variety of pharmaceutical projects.

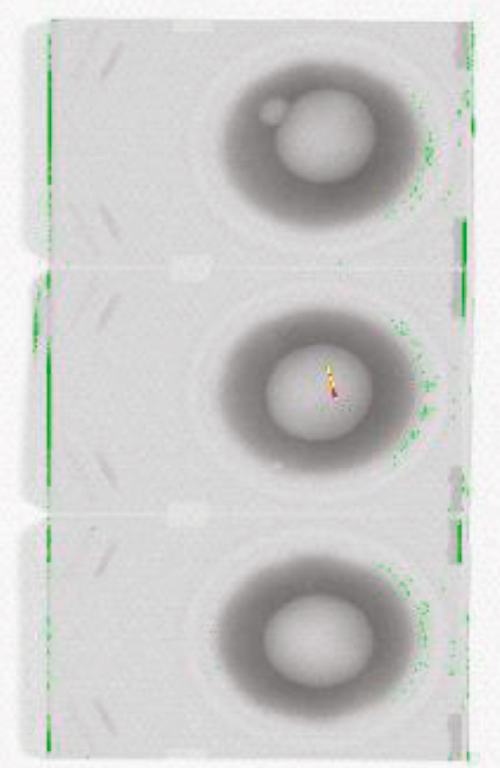

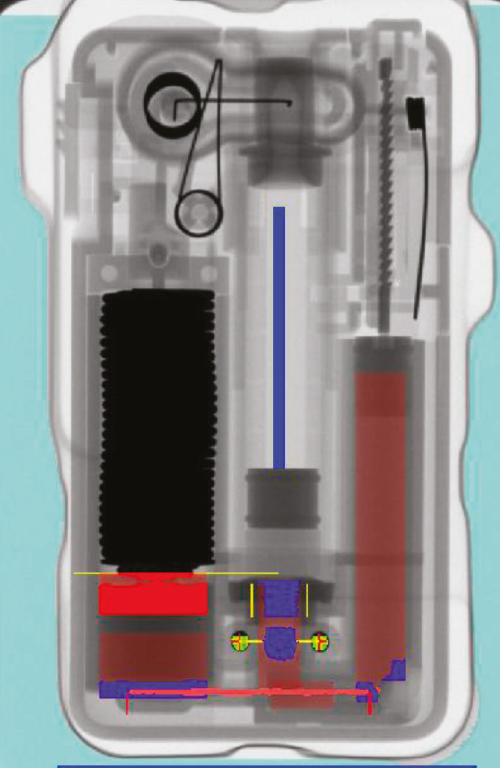

Sapphire systems combine low energy x-ray imaging with APS technologies, offering a resolution 10 times greater than traditional end-of-line x-ray technology and increased sensitivity.

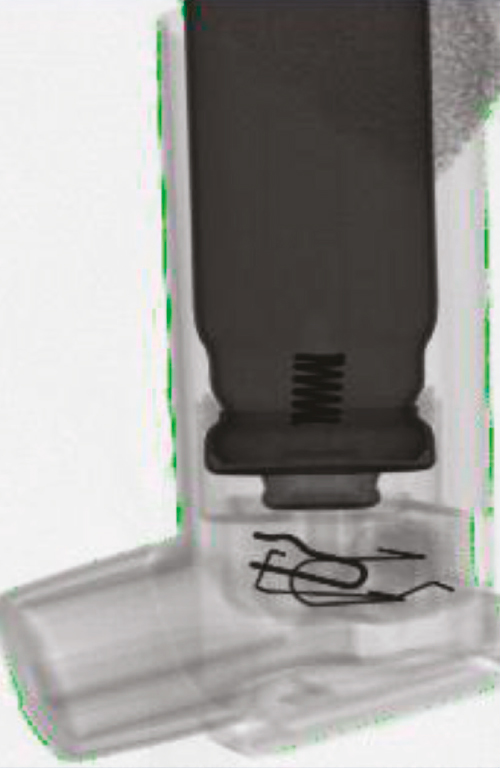

Checking drug delivery devices for product integrity, including pumps and injectable pens.

Inspecting liquid medicines for gas bubbles in imperative for safe delivery. We can detect gas bubbles as small as 0.3mm in liquids contained within plastic tubes such as GLP1 slow release osmotic pumps.

Sapphire’s systems can measure the dose level of powdered drugs to a repeatability of <0.1mg in dose carriers, including powder inhaler devices, peelable strips, ring carries and dosing from pellets.

The constant evolution within the pharmaceutical and medical industries demands highly skilled and experienced engineers to develop new applications for custom projects. Our talented and experienced R&D team have a solid understanding of the standards and demands for these fields, making custom project collaboration easier for your teams.

The A Series is a compact but sophisticated, entry level x-ray system for automatic, end of line inspection.

To introduce working life at Sapphire Inspection Systems we present the first in our series of team introductions.

Josh White has been with Sapphire for 8 years and has worked across numerous areas of the business.

Read More

In recent years the cost of x-ray systems has fallen and with entry level models available for the same price as some metal detectors the market is now in serious competition. So why should you choose x-ray inspection over metal detection?

Read More

We know that very little stops for manufacturers over the Christmas and New Year period.

Read More